What is a composite material?

Technically speaking, a composite material is any material that comprises at least two constituent materials, each with significantly different properties. The properties of the resulting composite are also different from those of the constituent materials. Frequently used in high-performance applications such as fighter jets, racing cars and high-end road bikes, it’s tempting to assume that composite materials must be a modern development, but nothing could be further from the truth. Composite materials have been around as long as the hills, and in some cases much longer… As with many great innovations, it’s fair to say that mankind was squarely beaten to it by mother nature in the development of composite materials: Everyday examples of naturally occurring composites include wood (strong cellulose fibres held together by much weaker lignin) and bone (hydroxyapatite which is hard but brittle, combined with flexible but soft collagen). In both cases, the resulting material is much more useful than either of its constituents in isolation. And of course, wood and bone represent two of the earliest engineering materials used by mankind!

But perhaps if we turn our attention to man-made composites, we’ll find that they’re all the stuff of modern cutting-edge engineering? Guess again! People have been making composite materials for donkeys’ years too, if not quite as long as mother nature. The picture below shows a couple of examples of early man-made composites. On the left, we have ‘cob’, a composite of clay, mud, sand and straw that represents one of the earliest building materials known to man. In this case, the straw inhibits the cracking of the hardened muddy mixture, producing an incredibly strong and durable construction. On the right, we have wattle and daub wall panels, frequently found in medieval buildings. Here, the wooden ‘wattle’ laths provide strength whilst the muddy ‘daub’ mixture keeps out the draughts.

Moving more towards modern times, we encounter reinforced concrete, which from the 1850s has combined the environmental resistance and mouldability of concrete with the tensile strength of steel to enable fantastic feats of civil engineering that would not otherwise have been possible.

It’s not until the mid-20th century that the materials we tend to think of today as composites begin to arrive on the scene. It’s worth at this stage introducing the concept of fibre reinforced plastic composites (FRPs, for short). Whilst not the only category of composite material out there, this is the type in which we’re most interested here. The functions of the constituents of FRPs tend to be the same across the board:- Fibres of some type or another are held together by a plastic ‘matrix’: The fibres provide the strength whilst the matrix lends cohesion and stabilises the fibres such that they may transmit compressive as well as tensile loads.

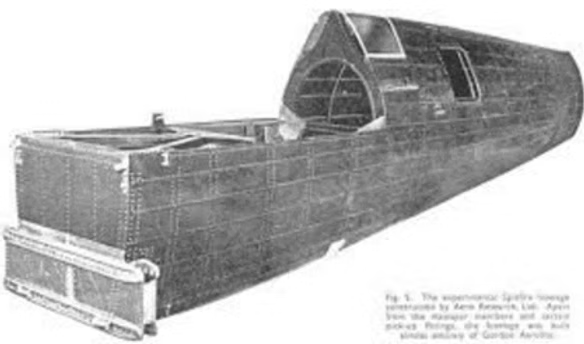

One of the earliest forays into the application of FRP composites for aero-structures was an experimental Spitfire fuselage below. Driven by the need to mitigate against wartime aluminium shortages, this was constructed in the 1940s from ‘Gordon Aerolite’ flax reinforced phenolic composite, and although never flown did pass the necessary static load tests.

Today, composite materials are very widely employed, from obvious applications such as aerospace, motorsport and wind turbine blades though to more obscure uses in oil pipelines and medical scanners, to name but a few.

Engineers are presented with a wide range of options from which to choose in terms of both fibre and matrix: Commonly used fibres include glass, carbon, Kevlar and flax, whilst matrix options include polyesters, vinylesters, epoxies, phenolics, bismaleimides (BMI) and thermoplastics. Each of these options offer differing properties and advantages relative to the others, so in future articles we’ll take a closer look at fibre and matrix properties.